|

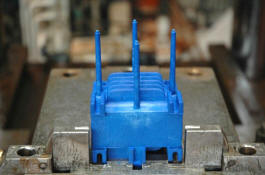

Construction of moulds:

GS Plastics

has the expertise to meet every requirement of the client. For 30

years, the company has accumulated wide-ranging experience in the

production of highly technical components.

This specialization distinguishes GS

Plastics in the field of thermoplastic molding and provides the

client the know-how that allows to realize each type of mould. The

collaboration between the customer and GS Plastics comes in 3

phases:

The design of the part

:

-

The engineering of the idea, i.e.

the assessment of the concept in all its aspects before becoming

a project,

-

The feasibility study with

particular attention to the simulation of the functionality and

the economic evaluation of the project,

-

For the simulations and the

realization of the 3-dimensional models, the company has at its

disposal a CAD-CAM system with software of the latest

generation, EDS - Unigraphics Nx,

-

The production of prototypes-samples

to verify the functionality and the specifications of the

product.

The design and the

realization of the mould :

-

Specialized technicians study the

design of the mould on the computer and determine the optimal

type of injection and other construction parameters,

-

The Tooling Department gets

automatically the data needed for the construction of the mould,

-

The Production Department with

presses between 30 and 270 tons allows to try out the mould and

to compare the results with technologically similar products,

-

Metrology and test room to verify

the specifications,

-

Sampling gives the possibility to

correct the product,

-

A pre-production is foreseen to get

the approval of the customer, prior to delivery of the mould.

Maintenance of the

mould :

|